Understanding the Basics of Abrasives

Abrasives are divided into two main categories: metallic and non-metallic. Each offers distinct characteristics and is suited to different applications, surfaces, and industries. The choice between them depends on factors such as blasting equipment, cost, environmental impact, recyclability, cleanliness and surface profile expected, and the surface being treated.

Metallic Abrasives: Power and Recyclability

1. What are Metallic Abrasives?

Metallic abrasives, including steel shot, steel grit, stainless steel shot, cast iron grit and all types of cut wire, are durable materials used in heavy-duty industrial applications. These abrasives are favored in industries such as automotive, aerospace, and construction due to their strength, high recyclability, and ability to withstand tough conditions.

2. Key Types of Metallic Abrasives

- Steel Shot: Round steel particles used for cleaning, peening, and surface preparation, ideal for producing smooth surfaces.

- Steel Grit: Angular particles used for aggressive cleaning and surface roughening, great for creating an anchor profile before coating.

- Cast Iron Grit: Angular particles used for aggressive cleaning and surface roughening, great for creating an anchor profile before coating. To be used only in Airblasting equipment.

- Stainless Steel Abrasives: Offer superior resistance to rust and contamination, making them ideal for food processing, aerospace, and automotive industries.

- Cut Wire: Available in as-cut or conditioned form, cut wire abrasives provide greater consistency and longevity, particularly in shot peening applications.

4. Environmental and Economic Impact

The environmental benefits of metallic abrasives, particularly stainless steel, are undeniable. They can be recycled multiple times, reducing the need for raw materials and minimizing waste. By opting for stainless steel abrasives like Stelux, companies also eliminate the need for post-blasting chemical treatments, making the process more sustainable.

Non-Metallic Abrasives: Versatility and Cost-Efficiency

1. What are Non-Metallic Abrasives?

Non-metallic abrasives are natural or synthetic materials that offer a wide range of applications, particularly for surface preparation, soft cleaning, and material removal. These abrasives are commonly used in industries such as construction, maritime, and energy.

2. Key Types of Non-Metallic Abrasives

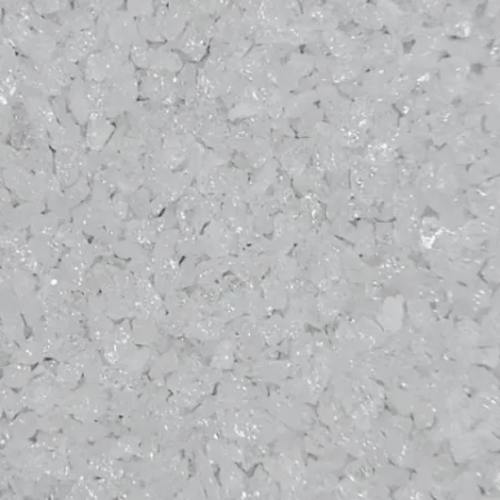

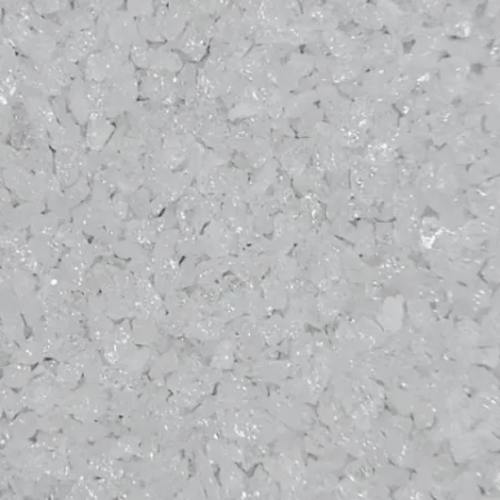

- Garnet: A natural mineral, ideal for both wet and dry blasting. It is widely used in surface preparation and water jet cutting applications.

- Aluminum Oxide: Known for its hardness and fast-cutting properties, it’s ideal for abrasive blasting and surface finishing.

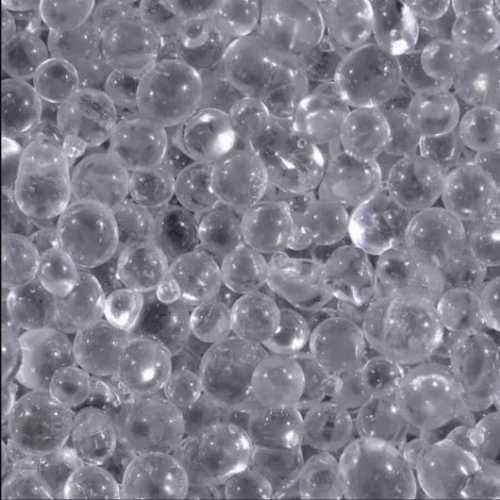

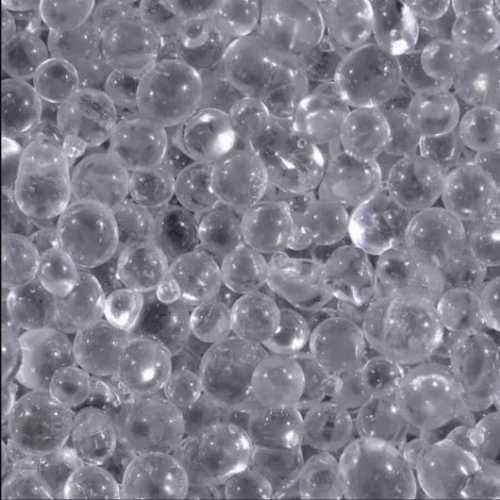

- Glass Beads: Used for soft cleaning and cosmetic finishing, especially on delicate surfaces like plastic and stainless steel.

- Vegetal Media: Eco-friendly and biodegradable, used for cleaning sensitive surfaces without causing damage.

- Plastic Media: Used in applications where delicate surfaces or light materials require careful handling, such as aerospace or automotive sectors.

3. Benefits of Non-Metallic Abrasives

- Cost-Effectiveness: Non-metallic abrasives tend to be more affordable for small-scale projects, making them a preferred choice in industries where budgets are a key consideration. The blasting machines able to use non-metallic abrasives are more simple with less equipment so less costly. An interesting option when the user doesn’t want to invest in a heavy equipment.

- Surface Versatility: These abrasives are ideal for a range of applications, from soft cleaning to surface preparation. For instance, aluminum oxide is known for its ability to remove rust and paint efficiently, while glass beads are perfect for finishing delicate surfaces without damaging them. These abrasives are not sensible to corrosion, that’s why they are preferred for blasting conditions in wet environment.

- Environmental Considerations: Many non-metallic abrasives, such as vegetal media and garnet, are eco-friendly and biodegradable, reducing the overall environmental footprint of blasting operations.

How to Choose Between Metallic and Non-Metallic Abrasives

When deciding between metallic and non-metallic abrasives, consider the following factors:

- Surface Material: Metallic abrasives are ideal for metal surfaces where strength and durability are critical, while non-metallic abrasives work well on softer or more delicate surfaces.

- Recyclability: If your project requires repeated use of abrasives over time, metallic options offer a longer lifespan and are more cost-effective.

- Blasting equipment: Metallic abrasives are dedicated for Wheelblasting and Air blasting, as long as there is a recovery system and an air washer to allow the bad particles to be removed and the good ones to remain in the blasting process. Non-metallic abrasives are more frequently used in Air blasting operations when there is no recovery system nor air washer.

- Environmental Impact: For projects prioritizing sustainability, non-metallic abrasives such as vegetal media and garnet are excellent eco-friendly options.

Consult our Optimizing Abrasive Use article for detailed tips on selecting the right abrasive for your specific needs.\

Maintenance and Operational Considerations

Whether you use metallic or non-metallic abrasives, regular maintenance of your equipment is crucial for ensuring consistent performance. Key aspects include:

- Monitoring Abrasive Size and Shape: Over time, metallic abrasives degrade and lose their effectiveness. Regularly screening or air washing and replacing them helps maintain productivity and surface quality.

- Maintaining Equipment: The wear and tear on blasting machines can affect the quality of surface preparation. Regularly inspect and replace parts like blades, control cages, and nozzles to avoid costly downtime.

Conclusion and Expert Guidance

Understanding the unique properties and applications of both metallic and non-metallic abrasives is essential to achieving optimal surface preparation results. Whether you need the recyclability and durability of steel shot or the eco-friendliness and versatility of garnet, choosing the right abrasive can make all the difference in your project’s success.

At Winoa, our technical experts are available to provide guidance on selecting the right abrasives and ensuring your blasting process is as efficient as possible. Contact our team today to discuss your specific needs and get tailored recommendations that will help you achieve the best results.