Metal surface treatment is an essential aspect of industrial manufacturing, impacting the durability, efficiency, and quality of metal products. This overview explores various critical applications, each tailored to specific needs and challenges in the field.

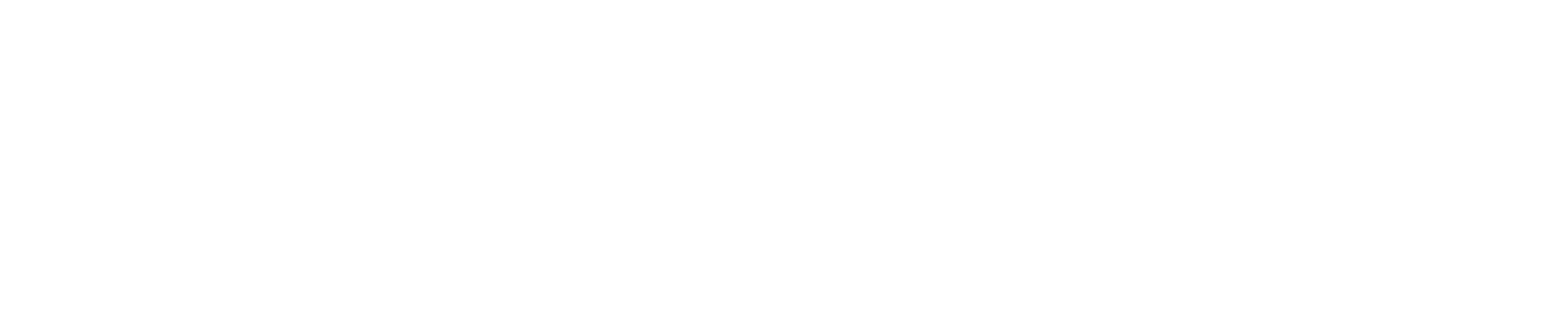

Descaling in Forging

Forging processes often result in scale formation on metal parts. Descaling in forging involves removing this scale to ensure quality and prepare the surface for further operations. Techniques include abrasive blasting with specific materials like S390 to S660 and GP18 to GP12.

Desanding in Foundry

After casting, metal parts in foundries are often covered with a layer of hard, sticky sand. Desanding ensures the removal of this sand, employing abrasives like S390 to S660 for clean and efficient preparation for machining operations.

Surface Preparation

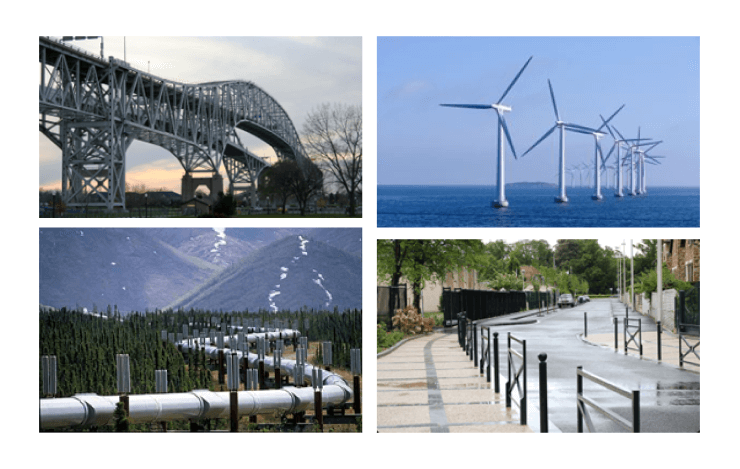

In general surface preparation, the focus is on removing scale or rust and creating a suitable profile for coating adhesion. Products like GP50 to GP25 and GL50 to GL25 are utilized, alongside specific machines, to achieve the desired surface quality.

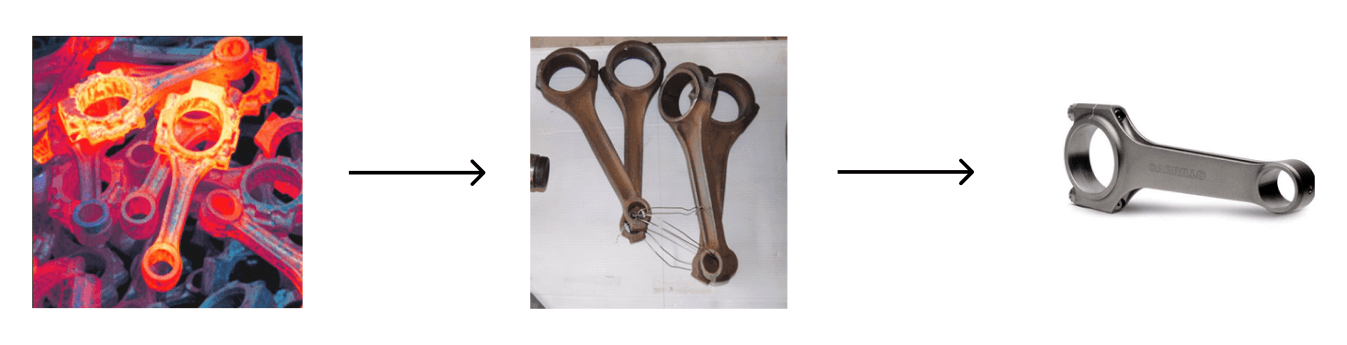

▲ Profiles in Industry

▲ Surface Treatment Before & After

Shot Peening

Shot peening is crucial for parts exposed to cyclic tension, such as in the automotive or aerospace industries. It involves bombarding the surface with shots (S110 to S460) to create compressive stress, significantly enhancing the lifespan of steel parts.

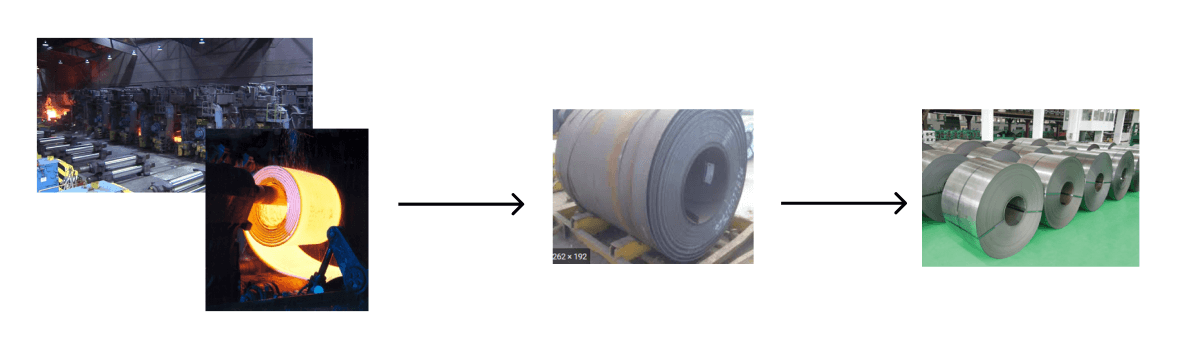

Descaling on Coils & Plates

After high-temperature lamination, coils and plates develop a scale layer. Descaling through blasting with abrasives like S170 and GP50 is necessary to extend the life of acid baths used in the treatment process.

▲ Descaling on Coils & Plates

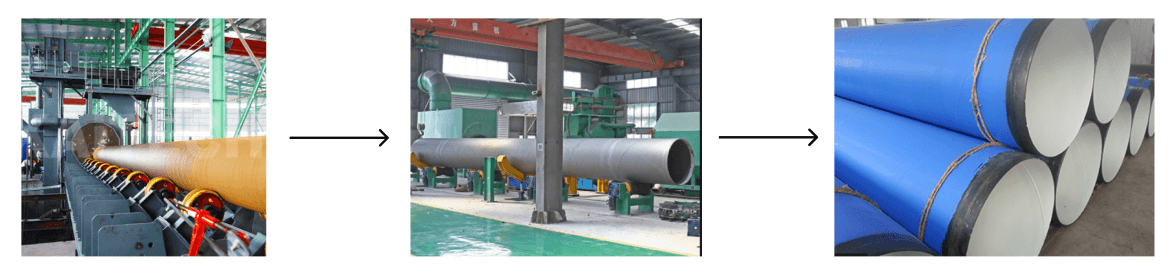

Surface Preparation for Pipe Coating

In the oil and gas industry, pipe coating requires precise surface preparation to ensure long-term durability. Techniques involve removing scale and rust and creating an optimal surface for coating adhesion, using products like GL40 and GL25.

▲ Surface Preparation for Pipe Coating