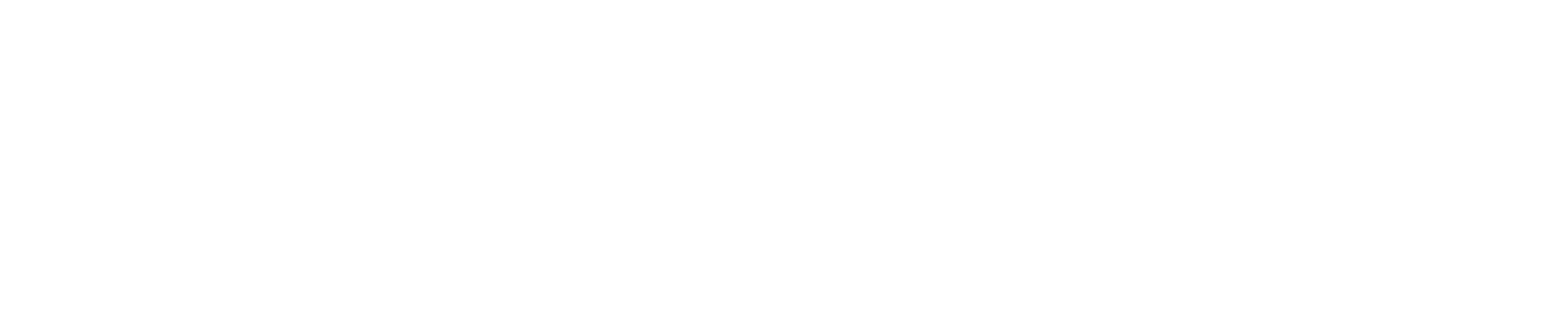

Desanding in foundry is a critical post-casting process that ensures the quality and functionality of metal parts. During casting, liquid metal is poured into a sand mold. Once the metal cools and solidifies, it emerges encased in a hard, sticky layer of sand. The primary objective in desanding is to remove this sand completely without damaging the part, preparing it for subsequent machining operations.

▲ Desanding in the fondry process

Understanding the Challenge

The sand used in molds adheres strongly to the metal surface and can be difficult to remove. This adherence is due to the high temperatures during casting, which can cause the sand to fuse slightly to the surface. Complete removal of this sand is crucial as any residue can hinder further processing steps and affect the quality of the final product.

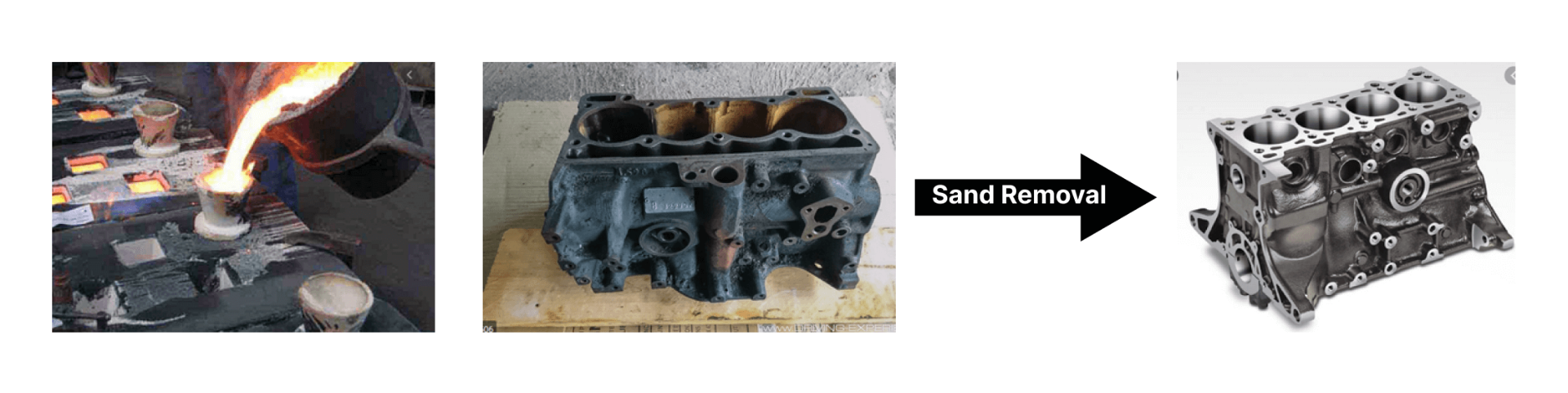

▲W Abrasive - Sand removal process by shot blasting

The Role of Abrasives

To tackle this challenge, specific abrasive materials like S390 to S660, GP18 to GP12, and HPG are employed. These abrasives are chosen for their ability to effectively remove sand without causing damage to the metal underneath. The selection of the right abrasive media is vital and depends on factors like the metal type and the extent of sand adhesion.

1. Blasting Techniques

Abrasive blasting is a common method used in desanding. This process involves propelling abrasive materials at high speeds towards the metal part to knock off the sand. The technique is highly effective but requires careful control to avoid damaging the metal surface.

2. Machine Types and Their Function

Various types of machines are used for desanding in foundries. These machines are designed to handle different sizes and shapes of metal parts, ensuring efficient and uniform sand removal. The choice of machine depends on the specific requirements of the casting process and the nature of the metal parts.

3. Ensuring Quality and Efficiency

Achieving a balance between thorough sand removal and maintaining the integrity of the metal part is essential. The process should be efficient to keep up with production demands while ensuring that each part is clean and ready for further processing.

Conclusion

Desanding is a main step in the foundry process, ensuring that metal parts are clean and free of sand before moving on to machining. Understanding the use of abrasive materials and the types of machines involved is key to achieving high-quality results in metal casting.