I need to do some painting, but there's oil left on the surface.

What should I do?

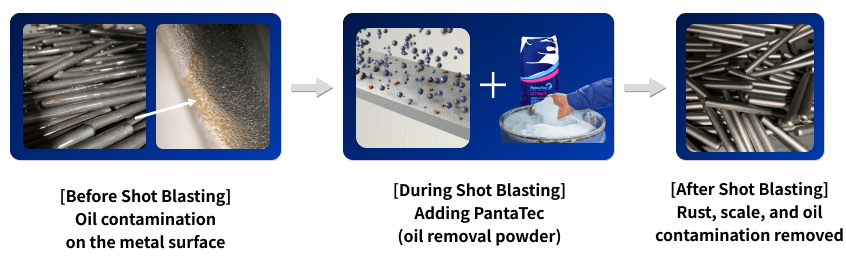

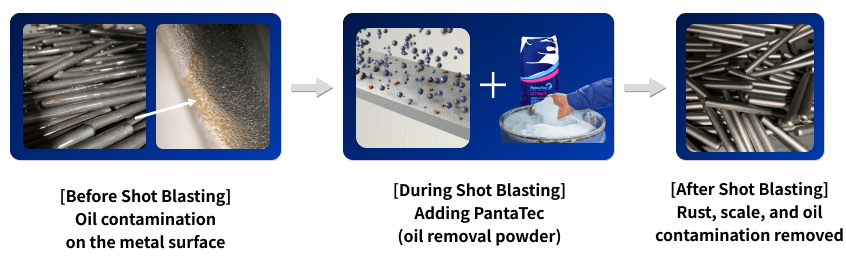

When it comes to painting, shot blasting is a crucial step. To ensure high-quality paint jobs, it's essential to remove scale, burrs, and rust from metal surfaces through shot blasting, achieving a clean surface. However, after the shot blasting process, residual oil can significantly reduce paint adhesion, leading to peeling paint. This problem often arises because oil contamination can occur on the surface of products that need blasting, usually due to the manufacturing process or sometimes by accident. Even though shot blasting can be done under these conditions, the oil on the surface will still compromise the coating adhesion. Additionally, if the abrasive gets contaminated with oil, it can spread the contamination to subsequent batches of products that were otherwise oil-free.

Many professionals in the shipbuilding industry face these challenges. Are you dealing with similar issues?

A: At our company, we use acid treatment to remove oil before painting. However, over time, the acid solution seeps out from holes, leaving white residues. When we paint over these areas, the paint doesn’t adhere well. Is there a good solution for this?

|

As you can see, various methods like acid treatment or using grinders are used to tackle oil contamination, but they often fall short or cause other problems. But what if there was no oil contamination in the first place?

"Shot Blasting and Degreasing: All at Once!"

Recently, a new solution has hit the market to address these issues: PantaTec™, a powder specifically designed for removing oil and grease. By mixing PantaTec with your abrasives during the shot blasting process, the powder absorbs the oil from the abrasives. This means it not only removes oil from the shot balls but also from the product surface, eliminating the need for an additional acid treatment after shot blasting.

Another problem with oil contamination is that when oil and dust mix during shot blasting, they create greasy, sticky dust. This sticky dust quickly clogs the shot blaster filters, significantly reducing the performance of air separators and dust collectors. Additionally, excessive dust inside the shot blasting machine can cause rapid wear on the machine’s internal walls and rotating parts, shortening its lifespan. However, using PantaTec to tackle the root cause of these issues helps prevent problems like "reduced paint quality" and "machine wear and tear" due to oil contamination.

Check out the video below to see how to use PantaTec and witness the effectiveness of our tests.