Airblasting operations are a critical component of surface preparation and finishing processes, demanding meticulous control over various parameters to ensure optimal outcomes. The effectiveness of airblasting is profoundly influenced by factors such as pressure, nozzle diameter, dust control, cleanliness, and surface roughness. Understanding the "why" behind the need for precise monitoring reveals the significance of achieving desired specifications, which in turn, enhances the quality, efficiency, and safety of airblasting operations.

Why Precise Monitoring Matters

Pressure Control

The consistency of air pressure directly impacts the uniformity and strength of the airblasting process. Precise pressure control ensures that the abrasive media is propelled at a consistent speed and force, resulting in uniform surface treatment and preventing damage to the substrate.

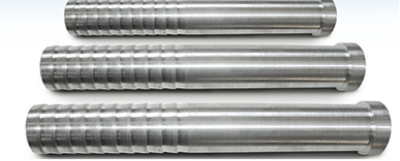

Nozzle Diameter

The diameter of the nozzle influences the velocity and distribution of the abrasive media. Monitoring and maintaining the correct nozzle diameter are essential for ensuring that the airblasting process is efficient and effective, minimizing wastage of media and energy.

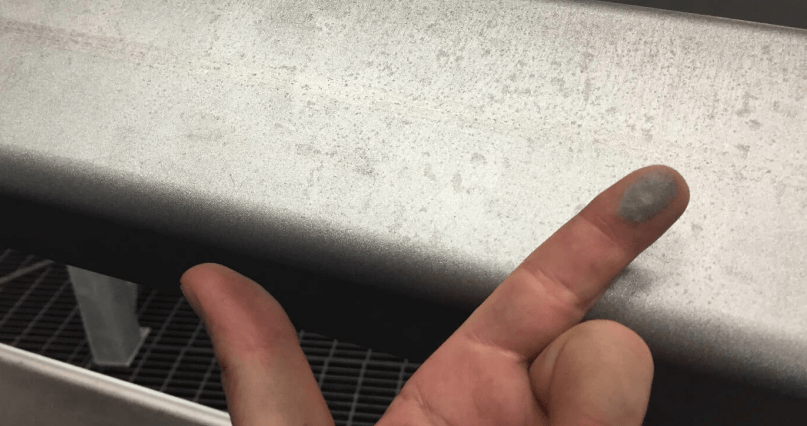

Dust Measurement

In applications where cleanliness and environmental considerations are paramount, controlling and measuring the dust generated during airblasting is crucial. Effective dust management not only meets stringent specifications but also protects the health of operators and prevents contamination of the work area.

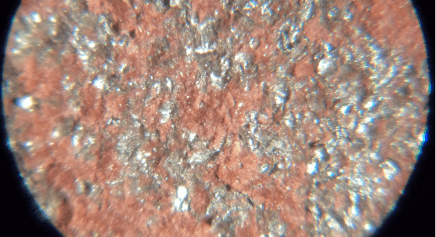

Cleanliness Measurement

The level of surface cleanliness after airblasting affects the adhesion and longevity of coatings. Precise cleanliness measurement ensures that surfaces are properly prepared for subsequent treatments, enhancing the overall quality of the finished product.

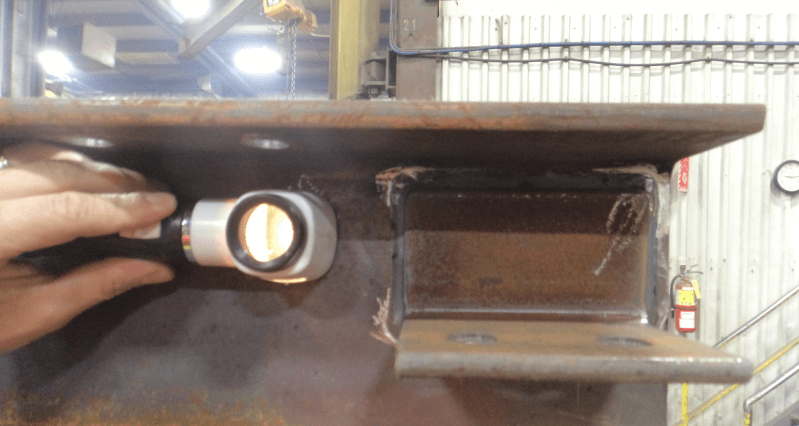

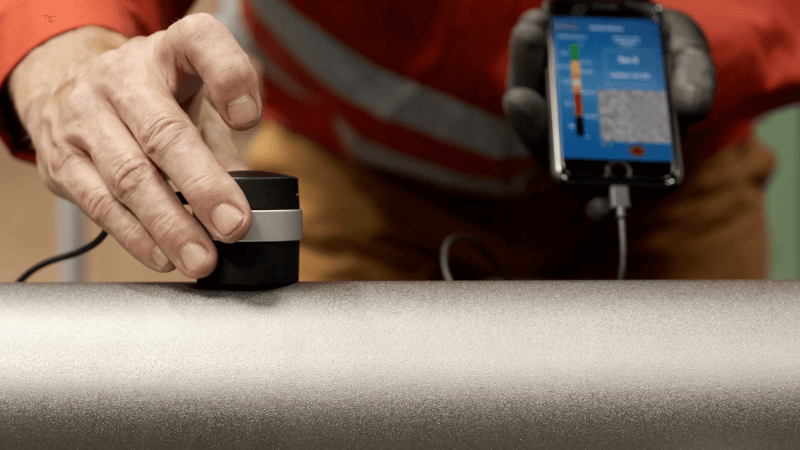

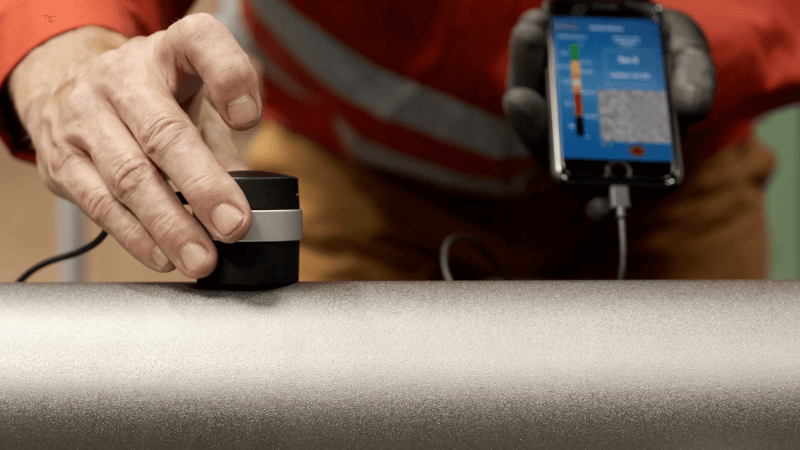

Roughness Measurement

The surface roughness achieved through airblasting determines the mechanical bonding of coatings. Accurate roughness measurement allows for the optimization of surface profiles, ensuring coatings adhere properly and perform as expected.

Integrating Advanced Tools for Enhanced Monitoring

To address these critical aspects, integrating advanced tools into airblasting operations becomes indispensable:

This tool allows for precise monitoring of air pressure at the nozzle, ensuring that airblasting operations are conducted under optimal conditions for uniform surface treatment.

For applications demanding high levels of cleanliness, the Dust Test Kit enables accurate assessment of residual dust, ensuring compliance with stringent cleanliness standards.

An automatic device for measuring surface cleanliness, WACLEAN provides quick, objective, and ISO-certified evaluations, ensuring surfaces meet official cleanliness standards.

Leveraging Expert Consulting Services

Beyond the use of sophisticated monitoring tools, leveraging expert consulting services can significantly enhance the efficiency and outcomes of airblasting operations. Our Consulting Services provide tailored advice and solutions, from selecting the right tools to interpreting data and making informed adjustments to your airblasting process. This combination of advanced tools and expert guidance ensures that airblasting operations achieve the highest standards of quality, efficiency, and safety.

Conclusion

The meticulous monitoring of airblasting operations through advanced tools and expert consulting services is essential for optimizing surface treatments. By emphasizing precision in every aspect of the process, from pressure control to surface roughness measurement, businesses can achieve superior results, ensuring their airblasting operations are both effective and efficient.